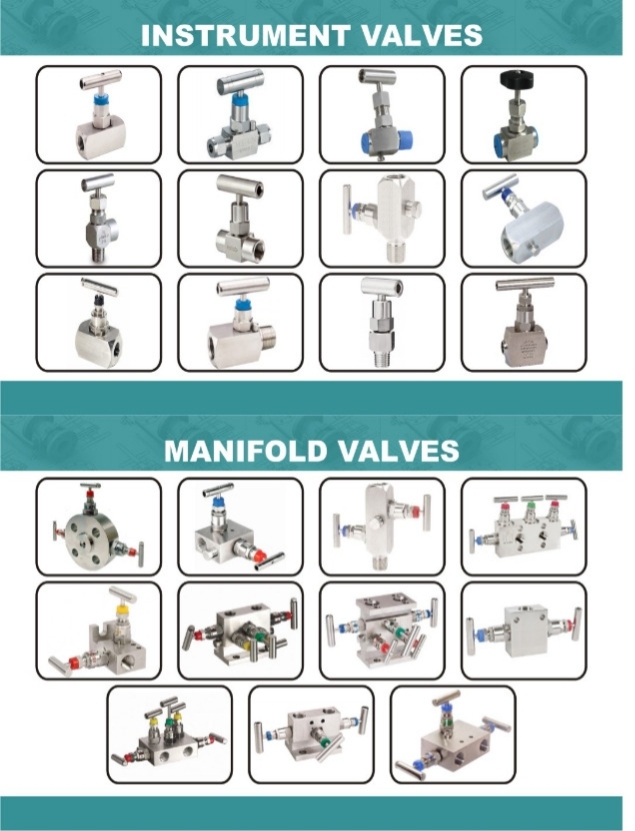

High Pressure Needle Valve

Price 600 INR/ Number

High Pressure Needle Valve Specification

- Valve Type

- Needle

- Material

- SS 304, SS 316 , SS 304 L , SS 316 L

- Valve Size

- 1/4 TO 2

- Connection Type

- Male & Female NPT, BSP, BSPT & tube fittings

- Usage

- Industrial

- Sealing

- PTFE standard and Alternate Graphoil

- Application

- Instrumentation

- Size

- 1/4" TO 2"

- Pressure

- High Pressure

- Media

- Oil

- Product Type

- Instrumentation valve

- Color

- Natural

High Pressure Needle Valve Trade Information

- Minimum Order Quantity

- 05 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Corrugated Box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About High Pressure Needle Valve

Needle Valve (Round Body)- Inlet & Outlet Connection Size:- 1/4", 3/8", 1/2", 3/4", 1" , 1.1/4" , 1.1/2" , 2"

- Materials Of Construction:- SS 304,SS 316 , SS 304 L , SS 316 L

- End Connections:- Male & Female NPT, BSP, BSPT, ISO tapered pipe ends Yakshita & tube fittings

- Maximum Operating Pressure:- 1000 PSI

- Minimum Operating Temperature:- 54 C -65 F

- Maximum Operating Temperature:- +538 C +1000 F

- Seat Material:- Metal seat and soft seat

- Packing Material:- PTFE standard and Alternate Graphoil

- Mounting Option:- Base Mount

Additional Information:

- Item Code: INV

- Production Capacity: 10000 PSI

- Delivery Time: One week

- Packaging Details: corrugated Box

Robust Construction for Reliable Performance

Engineered using superior stainless steel grades such as SS 304, SS 316, SS 304L, and SS 316L, this high pressure needle valve offers remarkable durability and corrosion resistance. It ensures consistent performance in critical instrumentation systems where high pressure management and longevity are essential.

Versatile Connections and Sizes

The valve supports a wide range of connection types, including Male & Female NPT, BSP, BSPT, and tube fittings, catering to diverse installation requirements. Available in sizes from 1/4" to 2", it seamlessly integrates with various industrial setups, enhancing operational flexibility.

Advanced Sealing for Leakproof Assurance

Equipped with PTFE standard and alternate Graphoil sealing options, the valve guarantees reliable sealing even in high-pressure environments. This feature minimizes maintenance, improves safety, and expands its suitability for handling different media, particularly oil.

FAQs of High Pressure Needle Valve:

Q: How is the High Pressure Needle Valve installed in instrumentation systems?

A: Installation is straightforward, as the valve is available with multiple connection typesMale & Female NPT, BSP, BSPT, and tube fittingsallowing integration into various pipelines or instrumentation assemblies.Q: What materials are used in the construction of this valve, and what benefits do they offer?

A: The valve is made from SS 304, SS 316, SS 304L, or SS 316L stainless steel, which ensures high strength, excellent resistance to corrosion, and suitability for harsh industrial environments.Q: Where can dealers, distributors, and traders source this valve in India?

A: This product is readily available through authorized dealers, distributors, exporters, suppliers, and traders across India, making it accessible for industrial procurement needs.Q: When should PTFE or Graphoil sealing be selected?

A: PTFE standard sealing is suitable for most general applications, while Graphoil should be chosen for higher temperature or more demanding conditions to ensure consistent leakproof performance.Q: What is the process for selecting the right valve size and connection type?

A: Consider your applications pressure requirements, media type, and existing pipeline fittings. Options from 1/4" to 2" sizes and various connections like NPT, BSP, BSPT, and tube fittings accommodate a range of setups.Q: How does the valve enhance control of oil flow in industrial settings?

A: Its needle design enables precise manual regulation of oil flow rates in high-pressure systems, ensuring operational accuracy and reducing risks associated with overpressure or leaks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

High pressure Ball Valve

Price 950 INR / Number

Minimum Order Quantity : 05 Units

Usage : Industrial

Pressure : High Pressure

Application : Instrumentation

High Pressure Safety Valve

Price 650.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Usage : For Hydraulic Pipe Use

Pressure : High Pressure

Power : Other

Application : Industrial

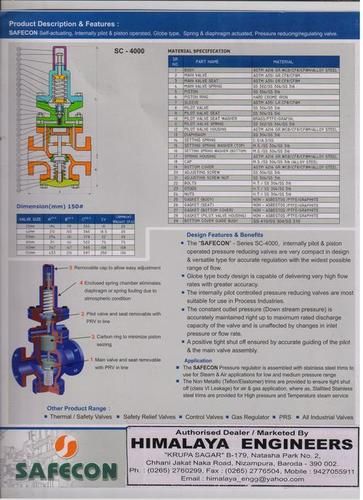

Pressure Reducing valve

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : for pressure reduction of STEAM in all types of Industries

Pressure : High Pressure

Power : Other

Application : for pressure reduction of STEAM in all types of Industries

Instrumentation Tube Fittings

Price 650 INR / Number

Minimum Order Quantity : 05

Usage : Industrial

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS