Instrumentation Tube Fittings

Price 650 INR/ Number

Instrumentation Tube Fittings Specification

- Material

- SS 304, SS 316 , SS 304 L , SS 316 L

- Usage

- Industrial

- Application

- Industrial

- Size

- Standard

- Product Type

- SS Tube fitting

- Media

- Gas

- Color

- Natural

Instrumentation Tube Fittings Trade Information

- Minimum Order Quantity

- 05 Number

- Payment Terms

- Others

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugatec box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Instrumentation Tube Fittings

Features

High-Quality Stainless Steel Construction

Our tube fittings utilize robust materials including SS 304, SS 316, SS 304L, and SS 316L. This ensures exceptional resistance to corrosion, making them the perfect choice for harsh industrial environments. With a natural finish, these fittings maintain their integrity and performance even after prolonged use, delivering reliability and longevity.

Comprehensive Distribution Across India

As an established dealer, distributor, exporter, supplier, and trader, we make these instrumentation tube fittings accessible throughout India. Our well-established supply network ensures prompt delivery and technical support, meeting customers demands for various industrial and instrumentation needs.

Optimized for Instrumentation and Gas Media Applications

Designed specifically for instrumentation setups and gas applications, these fittings maintain leak-proof connections and safe operation. Their size range from 1/4 to 1 accommodates common tubing dimensions, making them a versatile choice for diverse industrial systems.

FAQs of Instrumentation Tube Fittings:

Q: How do Instrumentation Tube Fittings benefit industrial gas applications?

A: Instrumentation Tube Fittings provide reliable, leak-free connections essential for safety and efficiency. With materials like SS 304, SS 316, SS 304L, and SS 316L, they offer excellent corrosion resistance, ensuring stable performance in demanding gas environments.Q: What materials are these tube fittings made of, and why are they suitable for industrial use?

A: These fittings are manufactured from high-grade stainless steel: SS 304, SS 316, SS 304L, and SS 316L. These alloys feature strong corrosion and chemical resistance, making them ideal for long-term use in various industrial processes, especially where aggressive or moist environments are present.Q: When are these fittings typically used in industrial settings?

A: Instrumentation Tube Fittings are used when precise control and monitoring of gas flow are required, such as in process control systems, laboratory setups, and any application where leak-tight, robust connections are paramount.Q: Where can customers purchase or source these tube fittings in India?

A: Customers across India can access these fittings through our widespread dealer, distributor, exporter, supplier, and trader channels, ensuring availability and support in major industrial hubs and remote locations alike.Q: What is the installation process for these tube fittings?

A: Installation involves cutting the tube to the required length, deburring the ends, inserting the tube into the fitting until it bottoms out, and tightening the connection according to the manufacturers guidelines. This process ensures a strong, leak-proof seal.Q: How should these tube fittings be used to maximize lifespan and safety?

A: For optimal performance, use the fittings within their specified pressure and temperature ratings, follow proper installation procedures, and regularly inspect them for signs of wear or corrosion. Proper use helps maintain safety and prolongs equipment life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

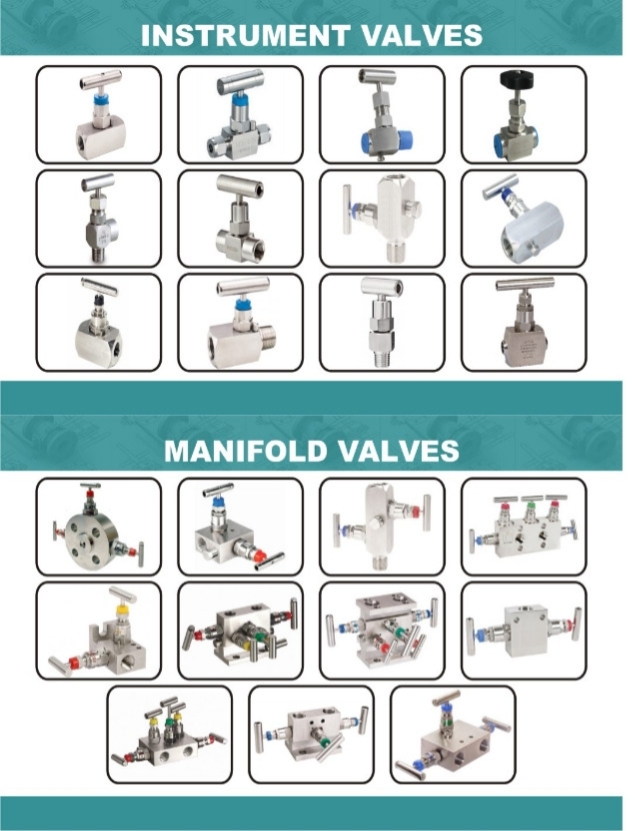

More Products in Industrial Valves Category

Valve Manifold

Price 2500 INR / Number

Minimum Order Quantity : 01 Number

Usage : Industrial

Pressure : High Pressure

Type : RType , TType , HType

High Pressure Safety Valve

Price 650.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Usage : For Hydraulic Pipe Use

Pressure : High Pressure

Type : Safety Valve

Width : 1020 Millimeter (mm)

High pressure Ball Valve

Price 950 INR / Number

Minimum Order Quantity : 05 Units

Usage : Industrial

Pressure : High Pressure

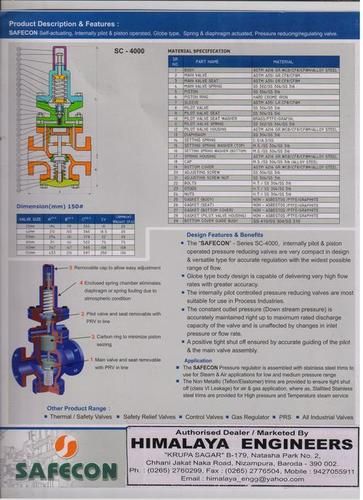

Pressure Reducing valve

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : for pressure reduction of STEAM in all types of Industries

Pressure : High Pressure

Type : Pressure Reducing valve

Width : 1020 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS