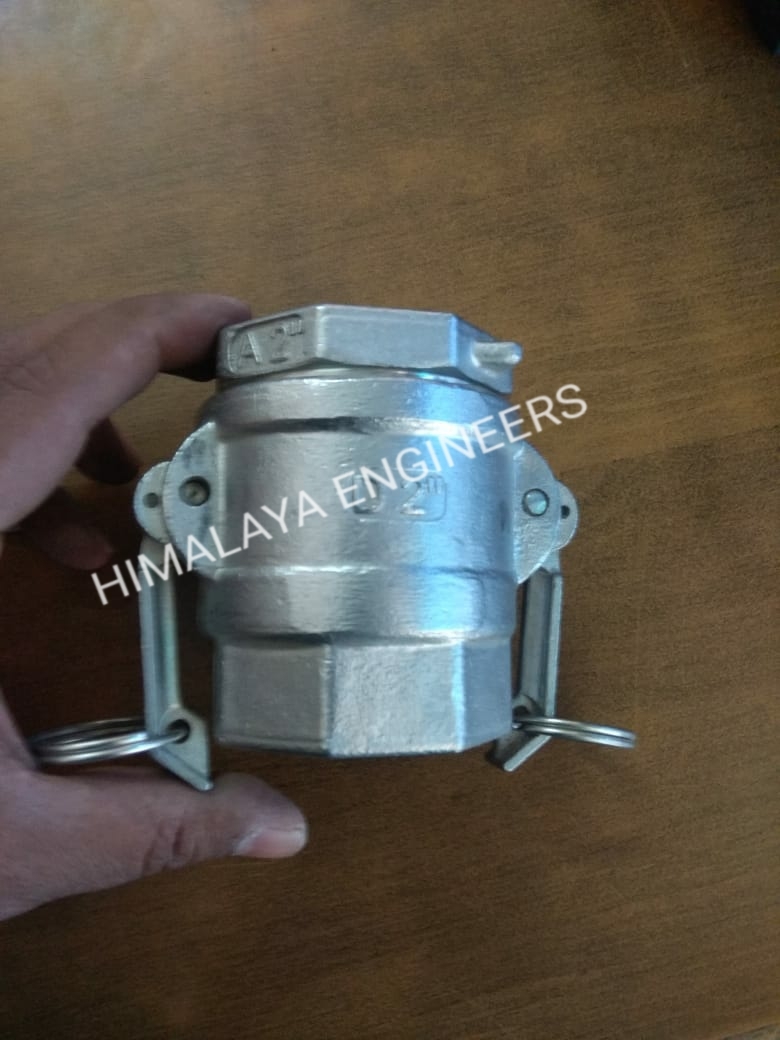

Camlock Coupling

Price 500 INR/ Piece

Camlock Coupling Specification

- Thread

- Male/Female/Hose End/Flange End

- Sealing

- Nitrile/Neoprene/Silicon/Teflon Etc..

- Material

- Stainless Steel

- Structure

- Other

- Size

- 1/2" to 6"

- Standard

- DIN-2838

- Product Type

- Camlock Coupling

- Surface Treatment

- chrome Plating

- Shape

- Bar

Camlock Coupling Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 7-8 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- corrugated Box

- Main Domestic Market

- All India

About Camlock Coupling

- Camlock couplings is in fact, a means of quick engaging of disengaging a hose connection from a system requiring transfer of fluid or gas.

- Camlock Couplings It consists of a COUPLER with cam arms and a slip in ADAPTER. In order to connect the Arm of the coupler need to be lifted and the adapter slipped into the coupler. The handle is then pressed down with normal hand pressure for a leak proof connection

- Camlock couplings Coupler & Adapters are available in different configurations.

- Camlock Couplings with With male and female threads (BSP,BSPT, or NPT)

- Camlock couplings with With hose shanks

- Camlock couplings With flanges or weld ends.

- Camlock Couplings are available in - Bar Stocks or casting type in various raw materials like Brass / SS304 /SS 316 / Carbon Steel.

- SEALING : Nitrile / Viton / Neoprene / Silicon / Teflon .

- SIZES : From 1/2" to 6" ( Higher sizes on special orders )

- WORKING PRESSURE : 5 kg/cm 2 to 20 kg/cm 2 (working varies according to the size of coupling )

- Cement,Fertilizers,Fire Fighting Equipment,Ink / Dye/Paint Industries ,Petrochemical / Refineries / Process Industries, Mining, Oil Drilling Companies (offshore / onshore ), Railways,Steel Plants, Military, Applications, Pneumatic Conveyors,Oil Blending Plants,Automobile manufacturers, Chemical Industries and Furnaces.

Robust Stainless Steel Construction

Fabricated from premium stainless steel with a protective chrome plating, these Camlock couplings resist rust and offer long-lasting reliability. Their robust build ensures dependable performance even under demanding conditions, making them ideal for a wide array of industrial uses.

Versatile Sealing Options for Every Need

Choose from nitrile, neoprene, silicon, or Teflon seals to match your specific application requirements. These options provide excellent chemical compatibility and leak-free connections for liquids, gases, and other fluids, enhancing safety and operational efficiency.

FAQs of Camlock Coupling:

Q: How do I select the appropriate size and thread type for my Camlock Coupling application?

A: To choose the correct size, determine the hose or pipe diameter you will be connecting, ranging from 1/2" to 6". For thread type, select among male, female, hose end, or flange end based on your piping system and connection requirements. Refer to DIN-2838 standards for guidance.Q: What surface treatment is applied to these Camlock Couplings and what are its benefits?

A: These couplings are treated with chrome plating, which enhances their resistance to corrosion and wear, provides an appealing finish, and makes cleaning easier. The surface treatment extends product lifespan, especially in harsh industrial environments.Q: When should I opt for different sealing materials like nitrile, neoprene, silicon, or Teflon?

A: Select the sealing material depending on the fluid or environment. Nitrile suits oils and fuels; neoprene resists acids and alkalis; silicon is ideal for high-temperature fluids; Teflon withstands aggressive chemicals. This flexibility ensures safe, leak-proof operation for varied applications.Q: Where are these Camlock Couplings commonly used in India?

A: These couplings are widely utilized in industries such as chemical processing, petrochemicals, agriculture, pharmaceuticals, and water treatment across India. Dealers, distributors, exporters, suppliers, and traders make them readily available throughout the region.Q: What is the process for installing stainless steel Camlock Couplings with bar shape?

A: Installation involves aligning the male and female ends or other compatible threads, inserting the bar-shaped coupling into the hose or pipe, and locking the cam arms to ensure a firm seal. Appropriate sealing material is used to prevent leaks and maintain integrity.Q: How does compliance with DIN-2838 standard benefit users and buyers?

A: Compliance with DIN-2838 ensures dimensional accuracy, interchangeability, and consistent quality. This international standard provides confidence in performance and facilitates seamless integration with compatible equipment and systems.Q: What are the key advantages of sourcing Camlock Couplings from Indian suppliers, dealers, or distributors?

A: Indian suppliers offer extensive product availability, prompt delivery, competitive pricing, and technical support. Their expertise and nationwide distribution make it easy to get genuine Camlock Couplings tailored for diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in QRC & Camlock Coupling Category

Stainless Steel Quick Release Coupling

Price 2,000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Quick Release Coupling

Shape : Round

Sealing : Nitrile, Viton, Neoprene, Silicon Etc..

Surface Treatment : chrome Plating

Pneumatic Coupling

Price 3500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Pneumatic Coupling

Shape : Bar

Sealing : Nitrle/Neoprene/silicon/Teflon

Surface Treatment : chrome Plating

Screw Type Coupler

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Screw Type Coupler

Shape : Round

Sealing : Nitrile, Viton, Neoprene, Silicon,PTFE etcc

Surface Treatment : chrome Plating

Quick Release Coupling

Price 1200 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Quick Release Coupling

Shape : Bar

Sealing : Nitrile/Neoprene/Silicon/Teflon

Surface Treatment : chrome Plating

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS