Stainless Steel Quick Release Coupling

Price 2,000 INR/ Piece

Stainless Steel Quick Release Coupling Specification

- Connection

- Other

- Sealing

- Nitrile, Viton, Neoprene, Silicon Etc..

- Thread

- metric , BSP, NPT , & in various end connection like hose shank , female,Male

- Material

- Stainless Steel

- Usage

- Industrial

- Structure

- Other

- Standard

- ISO 7241 -A & B

- Size

- 1/8" To 2"

- Product Type

- Quick Release Coupling

- Application

- Hydraulic/Pneumatic

- Width

- 5-10 Millimeter (mm)

- Surface Treatment

- chrome Plating

- Shape

- Round

Stainless Steel Quick Release Coupling Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Others

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 10-15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- standard

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Stainless Steel Quick Release Coupling

Stainless Steel Quick Release Coupling

These quick release couplings can also be custom made in required dimensions.We offer a wide range of industry leading selection of pneumatic & hydraulic quick disconnect couplings.

We have successfully Developed & Replace International Brands Like Hansen U.S.A, parket U.S.A, Nitto Japan, Walther Germany, Argus Germany,Martin Decker U.K., Adflow Etc..Etc.

| Usage/Application | Hydraulic/Pneumatic |

| Brand | HE |

| Material | Brass |

| Size | 1/8" To 2" |

| Thread Size | NPT OR BSP OR Hose End |

| Product Type | Single Check Valve OR Double Check Valve OR straight through |

Superior Material and Finish

Each coupling is made from high-grade stainless steel and treated with chrome plating, ensuring outstanding durability and corrosion resistance for demanding industrial environments. The round shape and precision construction support long-term reliability.

Versatile Connection Types

Designed to accommodate metric, BSP, or NPT threading, these couplings offer flexible installation options. With end connections like hose shank, female, and male, they seamlessly integrate into hydraulic and pneumatic systems across multiple industries.

Reliable Sealing Performance

Multiple sealing material choices including Nitrile, Viton, Neoprene, and Silicon ensure optimal performance under various operational conditions. This adaptability helps minimize leakage and enhances safety and operational efficiency.

FAQs of Stainless Steel Quick Release Coupling:

Q: How is the installation process for Stainless Steel Quick Release Couplings completed?

A: Installation is straightforward due to the quick release mechanism. Choose the correct thread type and end connection (hose shank, female, or male), securely attach to your hydraulic or pneumatic system, and ensure the seal fits correctly for leak-proof operation.Q: What types of applications are these couplings suitable for?

A: These couplings are ideal for industrial hydraulic and pneumatic applications. Their robust construction and reliable seals make them suitable for systems that require frequent connecting and disconnecting of fluid lines.Q: When should I select a particular sealing material (Nitrile, Viton, Neoprene, Silicon)?

A: The choice of sealing material depends on the operating environment. For general industrial use, nitrile is common; Viton is better for high-temperature or chemical exposure; Neoprene suits moderate conditions; and silicon is chosen for extreme temperatures or specialized requirements.Q: Where can I use these couplings in my operations?

A: You can deploy these couplings in any industrial setting that utilizes hydraulic or pneumatic systems, such as manufacturing plants, automotive workshops, and machinery operations, where fast and secure line connections are needed.Q: What benefits do customers gain from using stainless steel quick release couplings?

A: Customers enjoy enhanced corrosion resistance, fast and secure connections, reduced downtime during maintenance, and compatibility with various thread types and end connections, leading to safer and more efficient workflow.Q: Who supplies and distributes these couplings in India?

A: Dealers, distributors, exporters, suppliers, and traders located throughout India offer these couplings, ensuring ready availability for industrial consumers and project requirements nationwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in QRC & Camlock Coupling Category

Hydraulic Quick Coupler

Minimum Order Quantity : 1 , , Piece

Material : Other

Product Type : coupling

Shape : Bar

Surface Treatment : chrome Plating

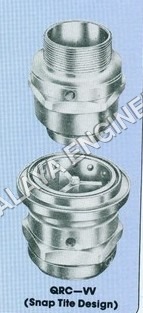

Snaptite Snaptite Q.R.C Coupling

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Product Type : Snaptite Coupling/ Snaptite Q.R.C

Shape : Bar

Surface Treatment : chrome Plating

Screw Type Coupler

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Product Type : Screw Type Coupler

Shape : Round

Surface Treatment : chrome Plating

Quick Release Coupling

Price 1200 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Product Type : Quick Release Coupling

Shape : Bar

Surface Treatment : chrome Plating

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS